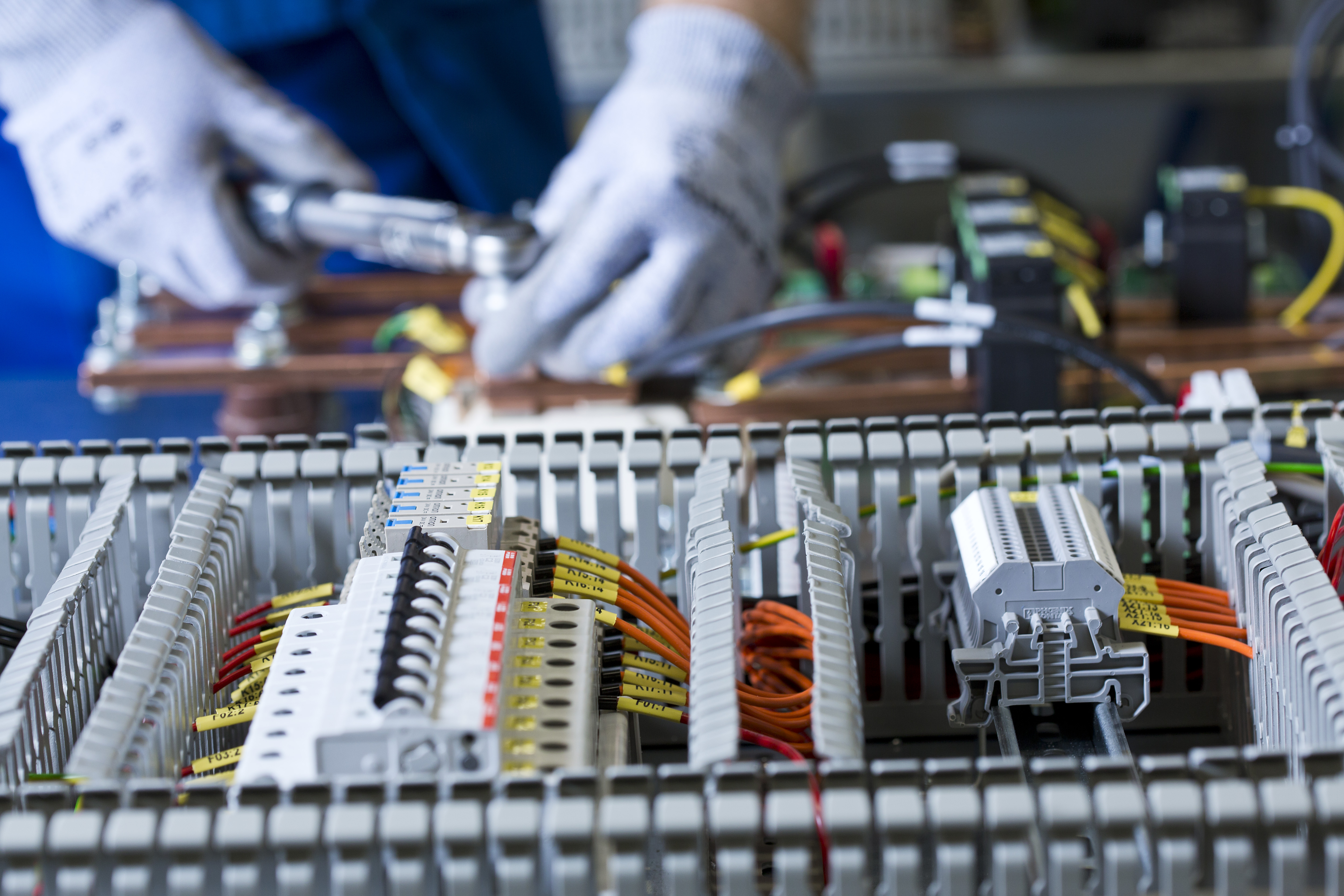

In 2002, Metso Automation Networks – today known as Valmet – signed a contract with Insta on the manufacture of automation cabinets. The companies have been working together for more than 20 years, and their partnership is based on demonstrably high performance and open dialogue.

– We look for partners that we can trust and with whom we can have an open discussion. For us, Insta is a familiar, reliable company: They are a trusted partner that consistently delivers high quality. Whenever there have been issues, we have been able to resolve them constructively. We have been happy to work with Insta for more than 20 years, says Valmet’s Supply Chain Engineer Petri Raiskila.

– It is important to have flexibility and the ability to make quick changes. Sometimes there are situations where manufacturing is ongoing, and you need to be able to stop what you are doing and make a U-turn. Not every company can do this. I would say that this is one of Insta’s strengths.